Stainless Steel Sheet

Stainless Steel Sheet

Stainless steel sheet are a vital material in many industries and businesses. They stand out for being very resistant to damage, strong, and good-looking. The top types are SS 304 and SS 316, each with benefits and uses. However, many other kinds of stainless steel are essential in different fields.

Key Takeaways

Over 1000 stainless steel sheet products are available on IndiaMART, including categories like 304 SS Sheet, Mirror Finish Stainless Steel Sheet, and Stainless Steel Coloured Sheet.

Different steel grades are available, such as SS304 L, SS441, SS410, SS304, SS309, and SS310, with corresponding price ranges from ₹160 to ₹501 per Kilogram.

Thickness options for stainless steel sheets commonly range from 0-1 mm to >5mm, with variations such as 1-2 mm, 2-3 mm, 3-4 mm, 4-5 mm, and greater than 5mm.

Leading suppliers like Manifold Pipe Solution Inc., Skyland Metal & Alloys Inc., and Sanghvi Metal Corporation offer a wide range of Stainless Steel Sheet products.

Customization options for stainless steel sheets include size, gauge, and surface finish.

Introduction to Stainless Steel Sheet

Stainless steel is made from iron and contains at least 10.5% chromium. This mix makes it resist rust. Chromium creates a skinny layer on the steel’s surface. This layer protects the steel from rusting.

Properties of Stainless Steel

- SS 410 is firm, complex, and used as a cutting and surgery tool.

- SS 430 resists rust well and shapes easily, found in buildings and cars. SS 409 is affordable, shapes and welds quickly, and is found in car exhausts.

- SS 441 does well in high heat and fights corrosion, and it is used in heat systems and exchangers.

- Then duplex types like 2205 and 2507 are needed for solid and rust-resistant marine and chemical work parts.

Applications of Stainless Steel Sheets

These sheets are used in many fields to demonstrate their unique abilities. Some places, including :

- Food processing uses it to clean containers, belts, and cooking devices.

- Buildings use it for solid and beautiful parts like walls and roofs.

- Cars, boats, and planes use it for exhausts, design parts, and whole structures.

- Chemical work picks it for its strong resistance to its harsh substances.

- Doctors and health workers use it for safe, rust-free tools and equipment.

stainless steel sheet, ss 304, ss 316, stainless steel

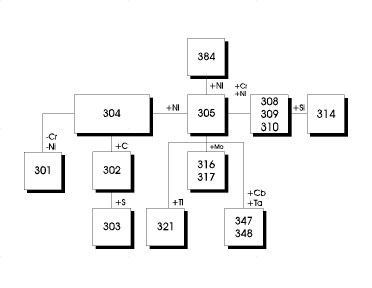

The popular SS 304 and SS 316 grades have unique benefits. Yet, many other stainless steel sheet grades are found in many industries. These include:

Other Popular Stainless Steel Grades

Jt, sd, Dd, 410, 430, 409, 441 j3, j4, 204cu – These types offer various properties. They’re used in food processing, construction, and cars. Companies keep a wide range to meet their clients’ specific needs.

How many stainless steel sheet are around can change depending on your location. Suppliers in essential places for making things worldwide keep different products. For example, India, China, and the U.S. have unique product lines. They help meet both local and worldwide needs.

Knowing about the different stainless steel grades helps industry pros choose well. They can pick the best for their project, like resisting rust, being very strong, or looking a certain way.

Manufacturing Processes of Stainless Steel Sheets

Stainless steel sheets start as hot, molten steel. This steel gets heated a lot and then rolled into thin sheets. It forms many shapes and finishes during this process. One finish it can have is called a “2B” finish, which is very common.

Cold Rolling

Besides hot rolling, stainless steel sheets can also be made by cold rolling. This happens without heat, keeping the steel cold. The cold rolling makes the steel thinner and smoother. It’s used to make stainless steel sheets look very polished, like for kitchen things or buildings.

Surface Treatments

After they’re rolled, stainless steel sheets might get unique treatments. These treatments make them look better, last longer, or work differently. Some ways to treat them are:

- Pickling and passivation to remove surface impurities and restore the protective chromium oxide layer.

- Brushing or polishing to create a range of surface finishes, from matte to mirror-like

- Coating or colouring processes to impart a specific aesthetic, such as a gold or black finish.

- Perforating or embossing to add visual interest and functional features

Stainless Steel Sheet Products

The stainless steel sheet market has more than just SS 304 and 316. It includes SS 410, 430, 409, and 441. Each grade has unique features for specific uses.

Mirror Finish Sheets

Stainless steel sheets with a mirror finish are loved for style. They’re perfect for luxurious spaces like kitchens, elevators, and architectural projects. These sheets are made shiny through a careful polishing process.

Perforated Sheets

Stainless steel sheets can be punched with patterns and shapes for looks and use. Perforated sheets help in places like facades, vents, and security screens. They make spaces look good and work better.

Checkered Sheets

Checkered stainless steel sheets have a raised pattern that grips well and prevents slipping. They’re great for safety in factories, docks, and stairs.

Colored Sheets

Tech lets stainless steel sheets come in colours like gold, rose gold, black, and blue. These colourful sheets beautify top-notch designs, highlighting beauty and sophistication.

Factors to Consider When Buying Stainless Steel Sheets

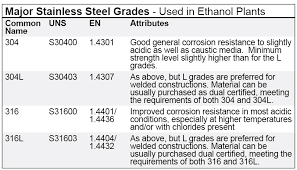

The material’s grade is vital when buying stainless steel sheets. Common grades like SS 304 and SS 316 are often seen, but many others exist. Each type comes with unique features and uses.

Grade Selection

Aside from versatile SS 304 and durable SS 316, you’ll find grades like SS 410, SS 430, SS 409, and SS 441. These options have different strengths. They can be easier to form, weld, or possess other essential traits.

Thickness and Dimensions

Stainless steel sheets vary in thickness from 0.5 mm to over 6 mm. The thickness needed depends on what you’re using it for. Lighter applications need thinner sheets, while heavier uses require thicker ones.

Surface Finish

There are different surface finishes for stainless steel sheets. These include shiny, embossed, and even perforated designs. Choose the finish that meets both the look and function you want.

Pricing and Availability

The cost of stainless steel sheets changes based on the grade, thickness, and finish. For example, SS 316 sheets are generally pricier than SS 304 ones. Consider what you need and if it’s readily available to meet your project’s deadlines.

Conclusion

Stainless steel sheets are a top choice for many projects. They offer robust and long-lasting performance for industrial and architectural uses. The standard grades include SS 304 and SS 316. But, there are more types with unique features and uses.

Other grades, like SS 410 and SS 430, are suitable for saving money and fighting rust. They are popular in making cars, appliances, and buildings. Then, there are unique types for special needs. SS J3, SS J4, and SS 204Cu stand out for more accessible machine work or better heat flow.

Knowing these different grades helps businesses and designers pick the best stainless steel. They can find a match for their unique project needs. With tools like online databases and Google Maps, the internet makes researching and finding suitable stainless steel easy.

Visit Our New Blog- https://ganpatiindustries.in/stainless-steel-supplier/